Here are the essential concepts you must grasp in order to answer the question correctly.

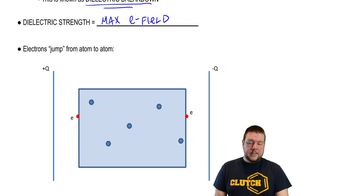

Tensile Strength

Tensile strength is the maximum amount of tensile (pulling) stress that a material can withstand before failure. It is typically measured in pascals (Pa) and is crucial for determining how much force a material can handle without breaking. For brass, this value varies but is generally high, making it suitable for applications requiring strength.

Recommended video:

Stress and Strain

Stress is defined as the force applied per unit area within materials, while strain is the deformation experienced by the material due to that stress. The relationship between stress and strain is described by Hooke's Law, which states that, within the elastic limit, stress is directly proportional to strain. Understanding these concepts is essential for calculating the required diameter of the wire to ensure it can handle the specified tensile force.

Recommended video:

Ray Diagrams for Convex Mirrors

Cross-Sectional Area

The cross-sectional area of a wire is the area of a slice taken perpendicular to its length. For a circular wire, this area can be calculated using the formula A = π(d/2)², where d is the diameter. The cross-sectional area is critical in determining how much stress the wire can endure; a larger area can distribute the force more effectively, reducing the likelihood of breaking under tension.

Recommended video:

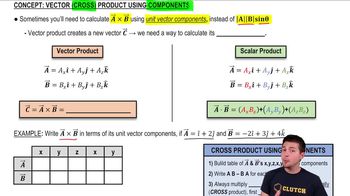

Calculating the Vector (Cross) Product Using Components