The Future of Design Education - a case study with King's College London

A future for higher education Engineering in the UK

King College London (KCL) boasts an engineering degree course that is rethinking how students are prepared for their eventual career in the industry. Claire Lucas, Professor of Engineering teaching and learning, was kind enough to open the doors on the undergraduate programme being developed, that might inspire teachers of design and technology to rethink how best to prepare students for an engineering degree pathway, if not through the vocational qualification route.

About the course

The undergraduate course attracts approximately 200 students, drawn from across the globe, who study engineering in the brand-new spaces on the lower ground floor of the University site near Somerset House. Ranked in the top 10 Universities in the world, the work of the engineering department to pioneer in the field of Engineering is an exciting prospect for current and future students.

The Spaces

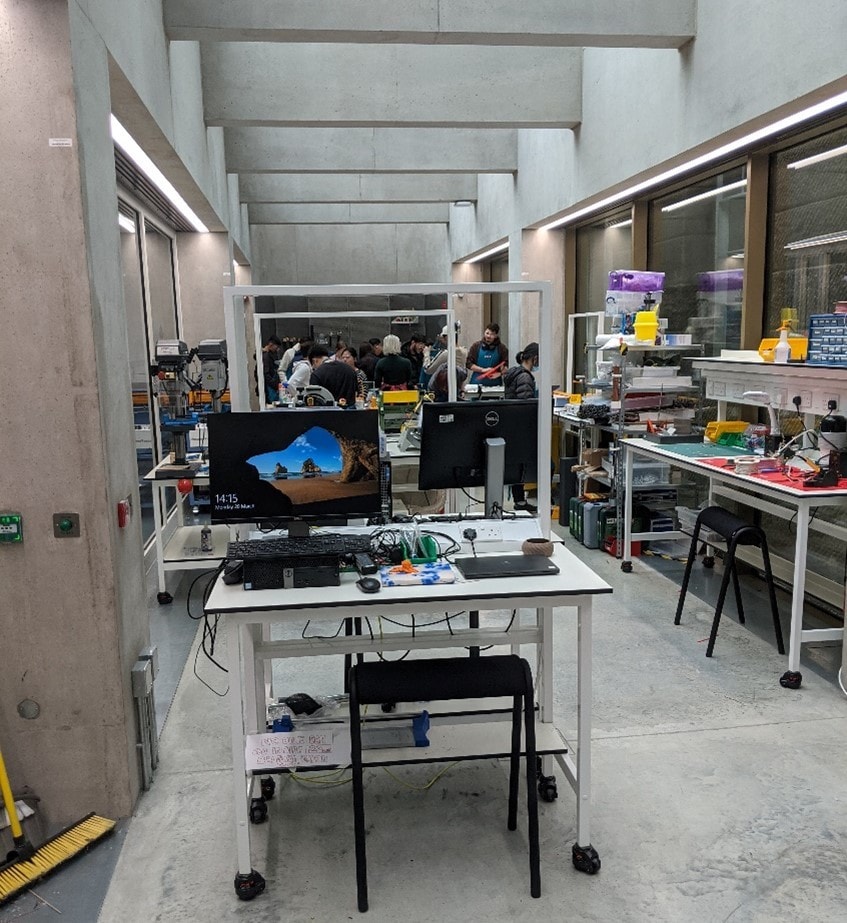

Upon entering the department, the spaces are bright, fresh and inviting. There are wide open rooms that can could comfortably seat 150+ students at a time, that are purposefully setup for collaboration. The cool grey paint and concrete surfaces look great, but what is so notable is the absence of large-scale machinery, typical of many engineering programmes, in this flexible space.

The Markerspace

Claire and the team are trialling lots of new ideas through this course. From a greater prominence for responsible engineering (social, ethics, cultural and inclusive priorities), to cleaner, flexible workspaces, makerspaces and collaborative assessment models, the aim fundamentally is to build the human capabilities of creativity, innovation and problem solving.

This looks and feels like a modern workshop typical of new or refurbished secondary schools, except that every item of equipment appears to be portable in some way. Ranging from soldering stations, hot wire cutters, forming machines and workbenches, the space is very busy with students, who are completing a collaborative first-year module assignment, and are supported by technicians.

The space is available for pre-booked periods of time, and to specific members of each team, so those working in there are typically under time pressure, whilst the other members of the team are outside working around tables on other aspects of the project.

CAD/CAM rooms

A permanent room houses laser cutters, 3D printers and a cupboard of consumable sheet materials such as laser ply or acrylic. Most of the equipment has a dedicated computer next to it, which streams a tutorial video of how to use the machine. This is typical of the course, where students learn how to operate machines, from the laser cutters to pillar drills, through watching a video.

For ease of use, the laser cutters have a set of pre-defined options for cutting, that means a student can process laser ply by simply opening the file, and selecting the pre-set material from an option list. The bed and laser autofocus, taking any issue out of student use. This gives students a large amount of freedom to use the equipment without technician support, though a fulltime technician is on hand in all of the spaces.

Collaborative spaces

Upon returning to the main open space in which the majority of undergraduates are working, there are a variety of things going on. Every student is crowded around laptops, whiteboards, in circles discussing the project, or trying to assemble their product on a table.

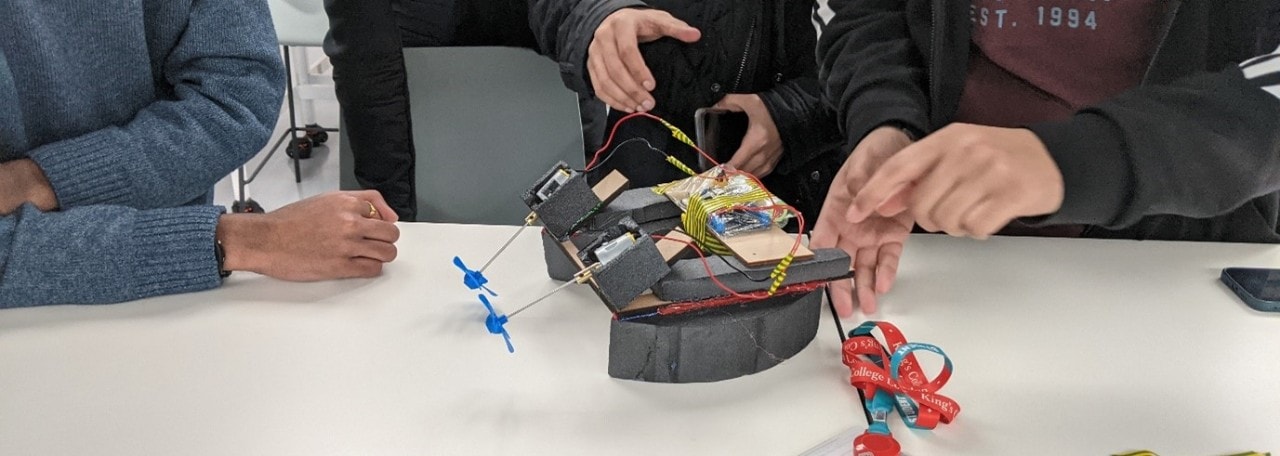

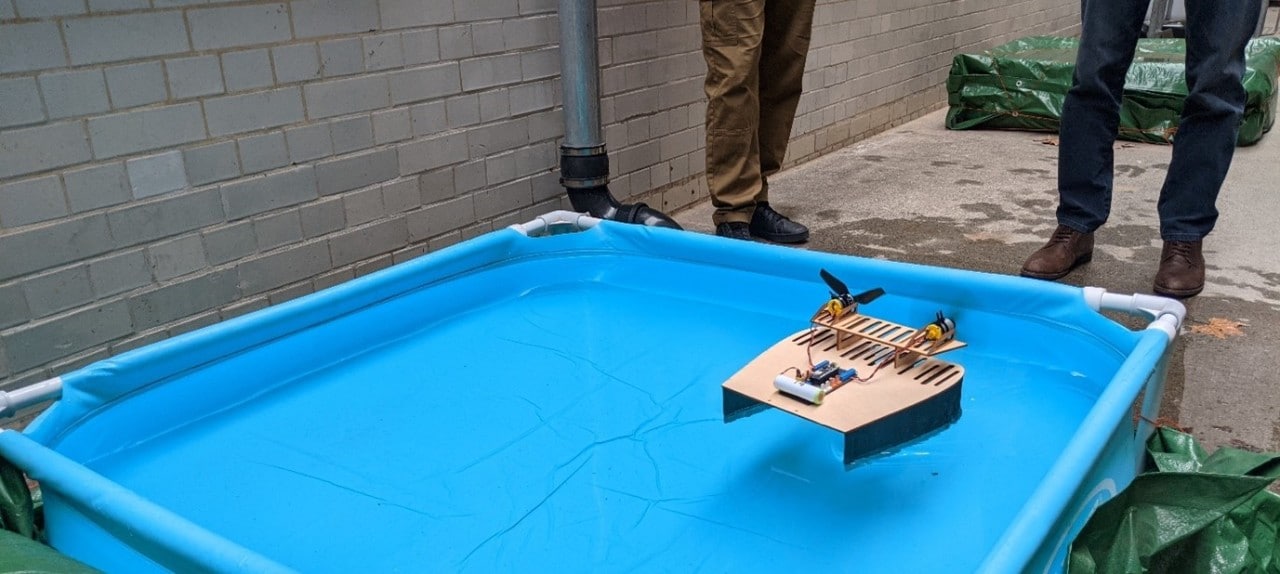

Their assignment is to prototype a boat that must navigate around a pool to gather floating objects. Off the shelf parts are available to every team, which include a set of motors, propellers (with plug and play CAD models of each option), and a control board, but the rest of the boat is up to the team. Some of the students are working on Autodesk Fusion 360, and appear to be either designing parts of the boat or simulating the boats performance in a virtual environment. This is a welcome proof of concept alongside the made boat, which is tested in a pool that sits outside in a courtyard.

Tokens and materials

In order for students to make the outcome, they need to exchange tokens for materials. Tokens are in short supply, equal in number to every team, but teams will receive additional assessment points if these tokens are unused at the end of the project. This makes new or virgin materials largely redundant wherever possible, with teams more willing to recycle materials and source scraps than draw from a body of virgin stock. Teams needing more tokens can exchange them with competitor teams, but the overarching priority for teams is to think responsibly about material consumption.

A different priority for Engineering

Claire and the team are trialling lots of new ideas through this course. From a greater prominence for responsible engineering (social, ethics, cultural and inclusive priorities), to cleaner, flexible workspaces, makerspaces and collaborative assessment models, the aim fundamentally is to build the human capabilities of creativity, innovation and problem solving.

When speaking to students, many who had completed their equivalent GCSE and A Level qualifications in another country, this degree course provides a wonderful experience of engineering from a leading University, that provides both the knowledge they need to succeed andt the right approach to engineering that cares for a society that the industry serves. From the cohort of undergraduates, almost none had studied a design or practical qualification before joining KCL, yet all were capable of building, prototyping and problem solving.

What can D&T departments learn?

The use of a Makerspace is something that is often mentioned as a solution for D&T departments who are unable to financially support a D&T workshop space in a secondary school setting. How it works at KCL also echoes the work of Cleapss around modular spaces. KCL plan to invest shortly in some lathe machines, but largely they are developing the curriculum first, and the spaces and equipment follow. For many D&T departments, the workshops and equipment can too often influence the curriculum more than the curriculum shape the workspaces.

For students looking at a career in Engineering, KCL is pioneering the way with a curriculum and space that develops those things that employers are looking for, teamwork, communication, collaboration and creativity, which year on year feature in the World Economic Forum skills for the future list, and where D&T education must focus. The need for past making experience is evidently not a requirement for this course, and the first year is accessible to all students from all backgrounds. In order to tackle the gender imbalance in engineering degree courses, KCL look to have taken a confident approach to a degree that feels welcoming, purposeful, and both develops and celebrates human capabilities at its heart.

-

Find out about our vision for the future of design education here.